Mosaic builds robust supply chain optimization solutions powered by artificial intelligence and machine learning.

Intelligent Supply Chain Management

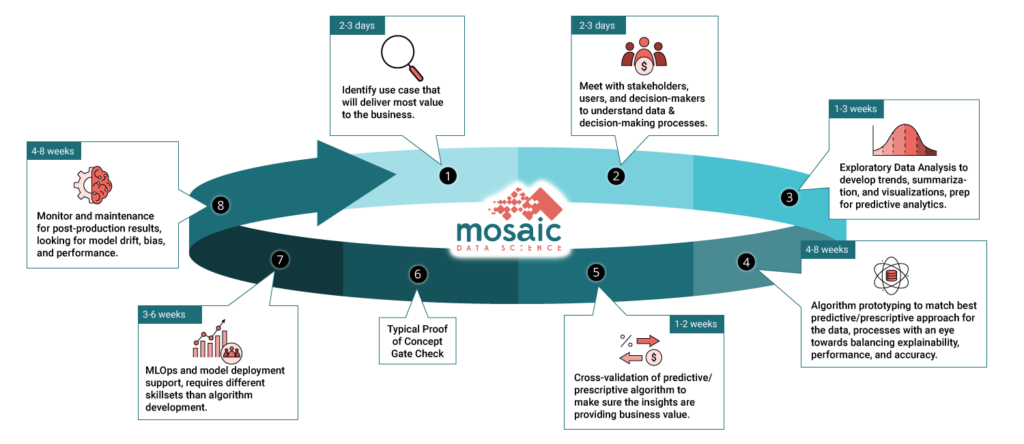

According to Gartner, 85% of businesses are still relatively immature in adopting analytics into their workflow. Companies who have resisted the wave of digital transformation are not only at a significant disadvantage of losing customers, but they are at extreme risk of closing their doors because they refuse to rethink operating models and leverage data and analytics to inform adaptations. Data analytics can deliver actionable insights incredibly quickly, and even if executives aren’t familiar with techniques, machine learning & predictive analytics can drive insights from data streams within weeks, not years.

Inventory optimization is a complicated component of supply chain management that is vulnerable to many internal and external factors. It involves having the right inventory to meet your demand, and buffer against unexpected disruption, while avoiding wasteful surplus. A successfully optimized inventory process will accurately forecast demand and respond quickly to both risks and opportunities.

Mosaic Data Science helps our customers futureproof their supply chains by leveraging data techniques like machine learning, mathematical optimization, deep learning, and agile software development to build custom applications that help everyone from hotels to energy companies make better supply/demand decisions.

Featured Success Stories & Insights

Advanced Industrial Inventory Management Analytics

Integrated Machine Learning and Mathematical Optimization

Combat Supply Chain Disruptions with Data Science

Price Optimization for Major Clearance Sales

AI-Enabled Retail Inventory Management

Oil Terminal Inventory Imbalance Prediction

Combatting Supply Chain Disruptions with Advanced Analytics

As the corporate world becomes increasingly more globalized, it is not uncommon for a company to move a product through multiple locations before it lands in a customer’s hand.

The increased complexity might be daunting to some managers, but from a data scientists’ point of view, these flows produce a ton of information that is ripe for analysis and can enable discovery of new opportunities. Customers now expect a certain level of service, and companies need to manage a complex network of plants, providers, suppliers, and buyers that enable them to remain flexible, operate efficiently, and meet customer demand.

AI Supply Chain Solutions Sheet