Summary

Mosaic helped an energy company optimize its hydrocarbon inventory management process by working with them to develop a centralized system to collect and control inventory data quality, improve accuracy, and improve the bottom line.

Take Our Content to Go

Why Intelligent Inventory Management Matters in the Oil & Gas Sector

The oil and gas market fluctuates wildly, with periods of highs and lows. Therefore, it is essential to know what you have in your inventory if you can afford to wait on replenishment for specific commodities, and even how low you can afford to sell your product based on supply and market demand. It is also essential to be as accurate as possible in measuring the commodities and products in your value chain. Companies need an automated hydrocarbon value chain that is resilient and can respond to dynamic market conditions.

Hydrocarbon management follows similar objectives to other inventory and distribution management problems but presents some unique challenges. Liquids and gasses are harder to quantify, transport, and store. Hydrocarbons are also unique in that any commodity can generally be broken down into a range of other intermediates and products. So, when you transport raw crude oil, for example, you are transporting dozens or hundreds of potential products, and tracking and optimizing to maximize those potential end products is very technically challenging.

There is also hedging and trading that occurs all along the value chain, so there are opportunities to gain value by selling intermediate commodities or even selling tank space, or “ullage,” to other hydrocarbon producers. In this case, an empty tank could be seen as an opportunity rather than a liability. If a hydrocarbon producer has free space in a tank, they can sell the available volume to other hydrocarbon producers, opening a new income stream.

Hydrocarbon producers can use ullage to store a cheap commodity until later to sell it at a higher price, or have the commodity refined into a product that is commanding a higher market price at the right time. This presents the opportunity for hydrocarbon producers to leverage their tank space by being efficient with volume, and Mosaic helped one of our energy customers accomplish exactly this.

A More Efficient Way to Collect Data

Before working with Mosaic, each hydrocarbon production site within the organization was responsible for tracking what was coming in and out of their facilities. This was done by collecting data from supervisory control and data acquisition (SCADA) systems and spreadsheets and then reconciling discrepancies between planned and actuals at periodic intervals. As one can imagine, this manual, inefficient process was costing our client time and money, as well as missed opportunities to add to their bottom line.

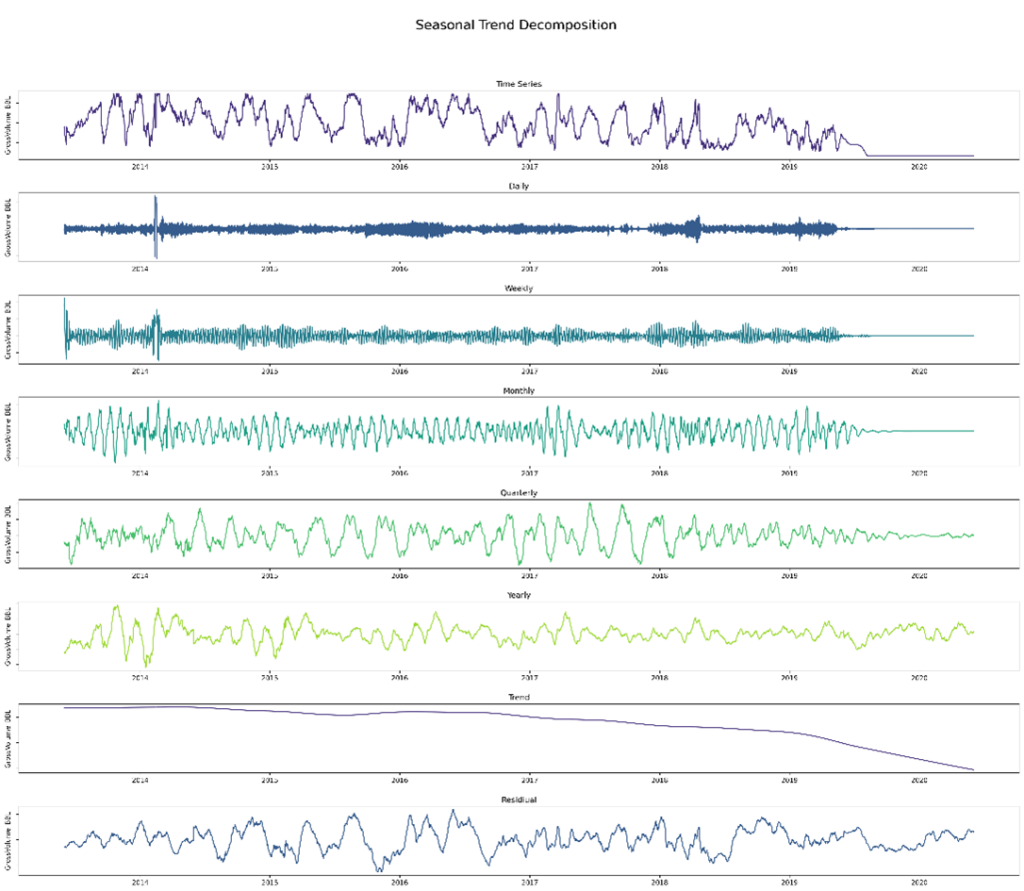

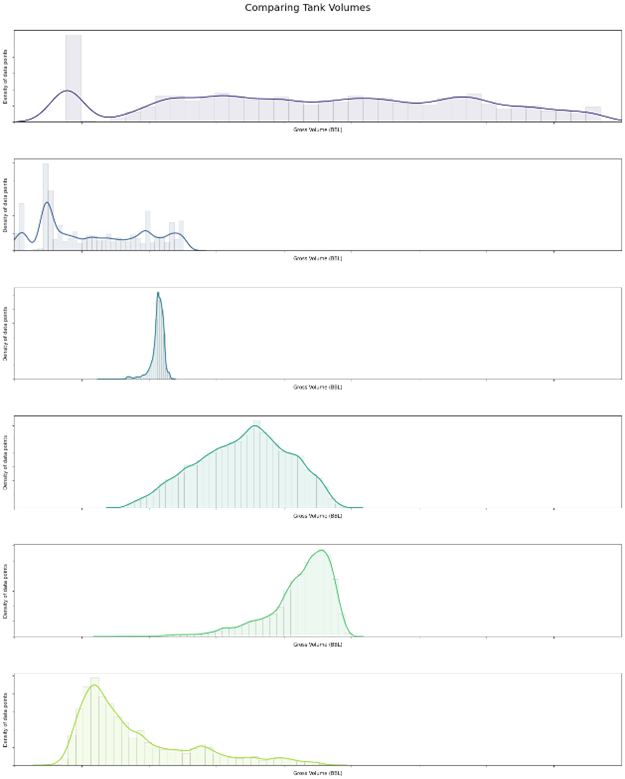

We were tasked with modernizing the way this customer moved and tracked its hydrocarbon inventory to better balance inventory levels and be more proactive in identifying and exposing available tank space. We achieved this by automating data collection and processing that gathers data from SCADA systems at individual sites into a centralized system, which the customer could then use to create reports and dashboards accounting for the inventories by commodity and regional hierarchies within their inventory management program.

Mosaic developed a process for quality control of inventory data and validating records. We did this by using a combination of domain knowledge and data engineering to identify and pull disparate data sources that were of high importance to the client. We also helped to develop certain performance indicators to be used for reporting which would help keep track of over- and under-utilization of tanks storing the inventory.

Having an outside voice in the room helped break down adoption barriers, trusting that an expert in data analytics could help build repeatable and scalable analysis practices.

Looking Ahead

Ultimately, this process can help the customer cut costs and produce more accurate free cash flow estimates based on the inventory they are carrying. A more streamlined inventory management system also opens up opportunities in the commodities storage market, creating additional revenue.

Digitizing and automating the hydrocarbon value chain can unlock additional hidden value for shareholders. The ultimate goal is to create an autonomous process that provides a digital thread of automation and transparency across the entire value chain for hydrocarbon management. This provides a complete map of an organization’s hydrocarbons, network, assets, costs, contracts, sales, partners, and customers to inform critical business decisions.