Summary

A hospitality technology disruptor was developing a new sensor suite to detect when a guest was smoking inside a property and distinguish it from approved activities such as cooking. They engaged Mosaic to build time series classification models to identify and alert on smoking events from the streaming sensor data.

Take Our Content to Go

IoT Machine Learning Need

Machine learning (ML) modeling for the analysis and classification of sensor signals has made substantial contributions to both research and development (R&D) and product development. IoT machine learning models can rapidly process large datasets, leading to quicker decision-making and shorter product development cycles. In fact, according to a study by McKinsey, organizations that deploy machine learning for product development report a 10-20% reduction in time-to-market.

The technology significantly boosts the accuracy of automated prediction and classification, enabling precise experimentation during R&D and creating high-quality products with fewer defects in product development. A survey by Deloitte found that 47% of product developers attribute improved product quality to machine learning integration. A model’s ability to automate repetitive tasks frees up professionals in R&D and product development to focus on more strategic aspects of their work. This automation extends to tasks like data analysis, allowing researchers to refine their strategies and product developers to tailor their designs to customer preferences.

Moreover, IoT machine learning modeling promotes data-driven decision-making, empowering R&D teams and product developers to adapt and innovate based on historical and real-time data insights. ML further contributes to cost reduction by optimizing resource allocation and streamlining processes. This helps facilitate continuous process improvement, allowing teams to refine their methodologies and release updates for existing products. Overall, machine learning has fostered efficiency and innovation in R&D and product development endeavors across diverse sectors.

Problem

A leading hospitality technology company’s R&D department had an advanced particulate monitoring device and wanted to develop a model to detect whether someone in a room is smoking and distinguish it from non-damaging activities such as cooking. If data from a sensor in the room is classified automatically and autonomously as smoking by a machine learning model, it would be able to alert owners and property managers in minutes to help them limit damage, reduce cleaning costs, and provide evidence of the identified behavior.

The company developed a device capable of measuring carbon dioxide, microscopic particulates, volatile organic compounds (VOCs), and other potential smoking indicators. Using this device, they conducted exploratory modeling using data collected in a controlled environment. To fully develop a machine learning model based on this data, and without the expertise on staff, the company turned to Mosaic.

Having developed and deployed machine learning models and decision support capabilities for various customers in the past, Mosaic brought its experience in applying innovative advanced analytics tools to inform critical business decisions and solve legacy problems. The collaboration benefitted from a flexible partnership and on-demand access to data scientists that filled their talent gap.

Mosaic collaborated with the company to finalize realistic data collection and labeling strategies and to develop a prototype machine learning model and support infrastructure that could process data from a 1,000-device alpha launch to detect and classify smoking. The project was deployed as part of a small pilot of the new device, signifying the company’s next step toward becoming a complete monitoring solution for property managers.

Data Collection and Labeling

In the first phase of the project, Mosaic collaborated with the hospitality technology company to provide input and advise on the data collection and labeling process to create a “gold standard” set of sensor data collected from realistic environments with corresponding high-confidence labels for the presence and type (vape, cigarette, marijuana, allowable [e.g., cooking or candle]) of particulate generating process.

The labeling process proved challenging regarding deployed devices, as many of the company’s customers would offer vague feedback, making it difficult to develop a baseline to evaluate model success accurately. The observed variability in deployed devices showed significant variation compared to what had been measured in controlled settings; training data did not represent the complete picture of the behavior of particulate-generating processes. In some cases, there were observations made from the deployed devices that could not be reproduced experimentally.

Given this, the training data set was limited, and the hospitality technology company could not measure or label more to build a more robust data set. Mosaic was challenged with creating a prototype model that would synthesize the available data to make an accurate prediction.

Prototype IoT Machine Learning Model Development

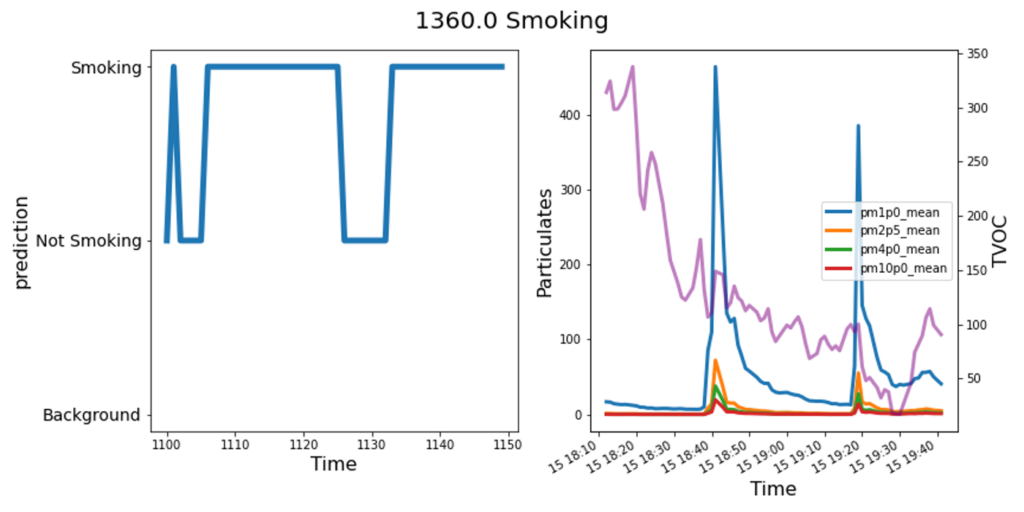

Using the small amount of training data measured in a controlled and well-documented environment, Mosaic developed and evaluated a model to identify and classify smoking behaviors based on their distinct signatures in the company’s sensor streams. Mosaic relied on a state-of-the-art time-series classification model known as ROCKET, which produced more accurate generalizations within the scope of the data available.

ROCKET models use an innovative randomized feature generation process to account for both short-term (e.g., sudden increases in particulates) and long-term (e.g., repetitive patterns as smokers take multiple draws from a cigarette) patterns in time series data while requiring significantly less training data and training much more quickly than neural network-based models such as LSTMs. This speaks to the importance of selecting the appropriate model based on the characteristics of a dataset, an effort that Mosaic’s data scientists had the in-depth knowledge to carry out successfully.

IoT Machine Learning Fig. 1: ROCKET model generating an alert for a case of a guest smoking in a hotel room

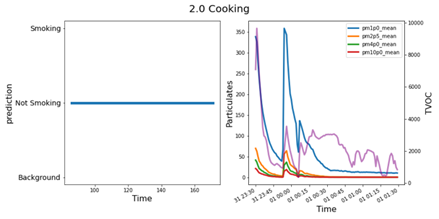

The initial prototype model operated offline, processing batches of sensor data on a centralized server, allowing Mosaic to evaluate and tune the model based on a desire to balance precision (minimizing the number of false positives – e.g., generating a smoking alert when someone is cooking on the stove) and recall (maximizing the likelihood of successfully alerting on an actual smoking event).

Mosaic collaborated with the company to select the final machine learning model that best met the dual objectives of accuracy and ease of deployment as a part of iterative prototype model development and evaluation before the alpha launch.

IoT Machine Learning Fig. 2: ROCKET model correctly identifying that a guest is cooking on a stovetop in a hotel room, avoiding a false alarm

IoT Machine Learning Model Deployment

The technology company ran an alpha deployment with more than 1,000 units in the field. With the company’s approval of the selected model, Mosaic collaborated to implement and deploy it within their existing infrastructure. The model was deployed on a central cloud where it processed data from the pilot devices in near-real time, flagging smoking events within seconds or minutes.

Mosaic worked with the technology company to determine the appropriate customer alerting logic to notify property managers when smoking was taking place, as well as integration points between the model and other internal processes, offering additional support for the deployed model during the pilot as an addition to the scope.

Conclusion

Mosaic was successful in the evaluation, development, and deployment of a model that could distinguish between particulate signals generated by smoking and those from other non-damaging processes, like cooking, via readings from a physical device. Throughout the project, Mosaic worked alongside the technology company’s stakeholders to gather feedback and ensure that Mosaic’s efforts aligned closely with their objectives and requirements.