Summary

Mosaic built a computer vision solution to improve the process of a vehicle moving through an automated carwash.

Take Our Content to Go

Once, the hardest part of getting right at the car wash was lining up the driver-side wheel with the conveyor track. Nowadays, the difficulties and risks of cleaning a car at the local automatic car wash are increasing, largely due to moving a car through the wash. This has resulted in many accidents across the country, leaving car owners and car wash operators at a loss for who is responsible for damages. Advanced car wash analytics can help operators derisk their operations and provide a streamlined experience.

To help solve this problem, Mosaic partnered with a leading professional services company specializing in planning and design services for car wash operators. The company invested in video technology over the past few years and wanted to leverage the data collected by these video feeds to improve the car wash experience. Using computer vision, Mosaic would develop and deploy scalable computer vision models to help properly guide vehicles into the wash and stop the conveyor if vehicles are misaligned before damage can be caused.

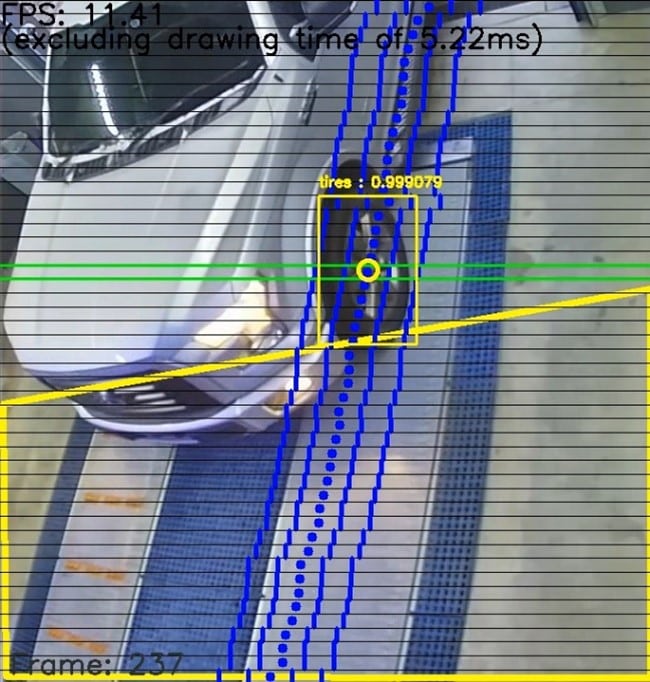

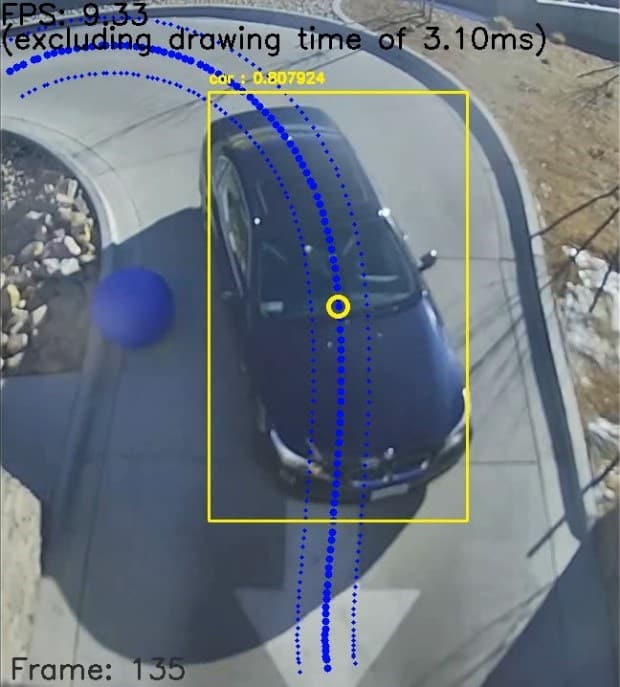

The goal was to help optimize the process of a car going through the wash tunnel by improving a vehicle’s alignment on the automated conveyor belt using a combination of live video feeds, computer vision processing, and digital signage. As a vehicle approaches the tunnel, the vehicle’s position is tracked using computer vision and compared with the position of historically aligned vehicles. If the vehicle is too far from the historical reference position, the application will signal to a signage device that will alert the driver to adjust accordingly. Additionally, the tunnel has similar monitoring cameras, ensuring that tires are properly aligned on the conveyor. This system can pause the conveyor if the vehicle is too far off track, decreasing the possibility of vehicle or wash equipment damage.

The project was split up into three phases. Mosaic collaborated with the professional services company to develop concepts for integrated computer vision insights into a controller system. Next, the team built custom vehicle and tire detection models, algorithms for comparing vehicle positions to historically observed positions, and components for communicating with external systems. It wrapped it all in a real-time processing application deployed to multiple live car washes.

Phase I: Creating a Recommended Architecture

In Phase I, Mosaic worked with the professional services company to design a hardware platform and accompanying software stack to achieve the use case the client was looking for. This included designing support for multiple hardware platforms and configurable signaling device interfaces to support unique product configurations.

Phase II: Computer Vision Model Prototyping

During Phase II of the project, Mosaic’s data scientists aimed to prove the viability of the computer vision approach using live video feeds. Preparation for data analysis involved reviewing the current data availability and checking the data quality. Due to the limited ability to collect training data, Mosaic opted to leverage Transfer Learning to train a preexisting computer vision model to specialize in vehicles and tires. Additionally, Mosaic focused on balancing the line between predictive accuracy and real-time performance.

Figure 1. Mosaic’s models automatically analyze the video and image data.

Once Mosaic established that vehicles and tires could be properly detected, they focused on designing and implementing algorithms for analyzing properly aligned vehicle movements and detecting misaligned vehicles. This algorithm had to be flexible enough to be deployed in a wide range of potential car wash configurations, including those with curved approaches. Additionally, the algorithm needed to be extensible to support multiple signaling modes, e.g., to stop the conveyor in the tunnel.

Phase III: System Integration

The project’s final phase involved wrapping the above components in a configurable and deployable software application. Mosaic supported the development of features to help operators get the application up and running on a site. This included wrapping the application in a Docker container for multiplatform support and easy deployment, automating historical data collection and decision algorithms fitting, developing interfaces to the car wash display system’s APIs for signage signaling and wash controls, and custom masking capabilities for unique region control and exclusion masking. Mosaic performed system testing and supported rollout to the company’s test facility.

The application supports deployment to NVIDIA Jetson devices for accelerated embedded performance. As the Professional Services Company seeks to ramp up deployment to more sites, Mosaic supports exploring AWS GreenGrass to automate Embedded CI/CD and AWS SageMaker for MLops.

Car Wash Analytics Results and Recommendations

Mosaic worked with the technology company to define, design, develop and deploy a custom machine learning application to inform car wash analytics. Mosaic continues collaborating with the company to refine features further and add additional capabilities such as detection use cases and remote configuration.